Researchers at MIPT have examined the propagation of ultrasound waves in composite materials.

The work has been published in the Lobachevskii Journal of Mathematics. In recent years, composite materials have gained recognition across various industries, including aviation and construction, due to their exceptional properties. However, ensuring their structural integrity and quality control poses significant challenges.

The research conducted by scientists from MIPT aims to enhance the understanding of ultrasound wave distribution dynamics in such materials by utilizing innovative modeling methods that promise to revolutionize non-destructive testing approaches.

This study introduces a new generation of methods based on hybrid grids and the grid-characteristic method, which together create a powerful tool for describing wave dynamics in isotropic linear elastic media. This research allows for a deeper understanding of the mechanisms of ultrasound wave propagation, opening up new opportunities for analysis and diagnostics of composite structures. The researchers chose an isotropic linear elastic medium as the primary model to gain insights into the impact of internal structure on wave processes. The grid-characteristic method, applied on both structured and curvilinear grids, enables highly accurate representation of wave interactions at material boundaries.

A distinctive feature of the method employed by the scientists is the integration of hybrid grids into a single background grid. In this case, the background grid has discontinuities in elastic parameters at the interfaces between different materials. Hybrid grids, positioned on either side of these discontinuities, serve to represent individual structures with a high level of detail within their boundaries. The elastic parameters at the nodes of the overlaid hybrid grids are determined based on the fundamental parameters of the background nodes. This approach allows for independent solutions to be found in each separate computational grid for the subsequent time step.

The solution process unfolds independently on each grid, providing results for the next time step. Afterward, the variable values at the nodes of the background grid are refined through interpolation from the overlaid hybrid grids. This approach eliminates the need for more complex methods to account for discontinuities in the background grid, optimizing the computational process.

A crucial consideration in this holistic approach to modeling ultrasound propagation is seamless parallelization of computations. The background grid is spatially partitioned into distinct areas where computations are carried out in parallel. In the hybrid grids, computations for individual heterogeneities are performed independently of other structures. This autonomy allows each core to efficiently manage the required number of structural grids.

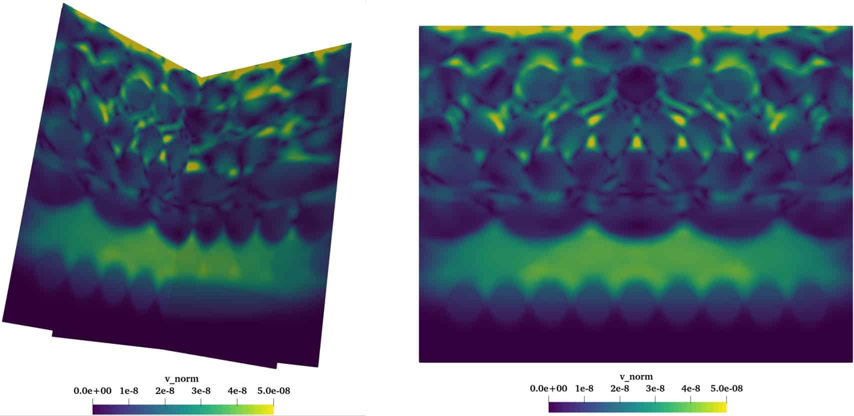

The method was applied to investigate the propagation of ultrasound waves in a composite material composed of eight layers of cylindrical fibers oriented at various angles and embedded in epoxy resin. The cylindrical fibers have a radius of 0.1 mm. The physical dimensions of the simulation area are 1 cm x 1 cm x 2 mm. The computational grid supports a step size of 0.001 mm, and although the curvilinear grids introduce distortions, the step variation does not exceed 1.5 times that of the background grid. The chosen temporal resolution was a time step of one nanosecond, and the total simulated time was one microsecond.

The method accounts for more complex fiber shapes beyond the simplified cylindrical form. The adhesion boundary condition is set at the interface of the external and internal hybrid grids, defining the fiber boundary. Non-reflection conditions were specified at the boundaries of the computational area.

The modeled ultrasound source took the form of a pulse corresponding to a fourth-degree sine wave, with a frequency of 20 MHz. In modeling the materials, a continuous elastic medium model was used, with parameters derived from the properties of real materials: longitudinal sound wave speed, transverse sound wave speed, and material density.

The simulation results demonstrated the dynamics of wave propagation within the composite material. A comparative analysis revealed that the new method outperformed the traditional approach based on variable elastic parameters by providing a finer consideration of the material's microstructure and yielding more reliable results.

“Traditional modeling methods are often developed based on anisotropic models, which do not always accurately capture the nuances of the microstructures of composite materials,” explained Evgeny Pesnya, a researcher in the Department of Computational Physics at MIPT. “The developed approach overcomes these limitations, providing researchers with the tools for in-depth analysis of ultrasound wave interactions, ensuring a detailed understanding of wave front behavior, particularly at material interfaces.”

“The grid-characteristic method, which served as the foundation for this research, allows for a more accurate description of wave processes, eliminating issues associated with classical finite element methods. As a result, new modeling technologies emphasize microstructural features and their impact on ultrasound propagation. This further underscores the importance of adapting approaches to modern requirements and standards of non-destructive testing,” added Igor Petrov, Corresponding Member of the Russian Academy of Sciences and Professor in the Department of Computational Physics at MIPT.

This research, based on a combination of advanced methodologies, promises to make a significant contribution to non-destructive testing and monitoring of aviation structures, as previously employed approximate anisotropic models fail to account for all types of waves in composite materials, according to studies by foreign colleagues. The developed methodology enhances the understanding of complex interactions and dynamic phenomena occurring in composite materials. With each new advancement, scientists are approaching a more accurate and effective monitoring of structural conditions. Further development of modeling techniques will serve the interests of safety and reliability in the most challenging engineering tasks.

The research is supported by a grant from the Russian Science Foundation.