Materials scientists have developed a conductive film made from starch.

In the long term, the electronics market's shift towards biopolymers, such as starch, will allow for a reduction in reliance on scarce and petrochemical resources, while also significantly decreasing the volume of toxic waste accumulating globally. The necessity for replacing gadgets is growing as rapidly as the production rates increase. This amplifies the demand for innovative solutions in eco-friendly electronics: devices that consume less energy, are made from accessible and affordable materials, theoretically decompose in nature, and do not require landfilling.

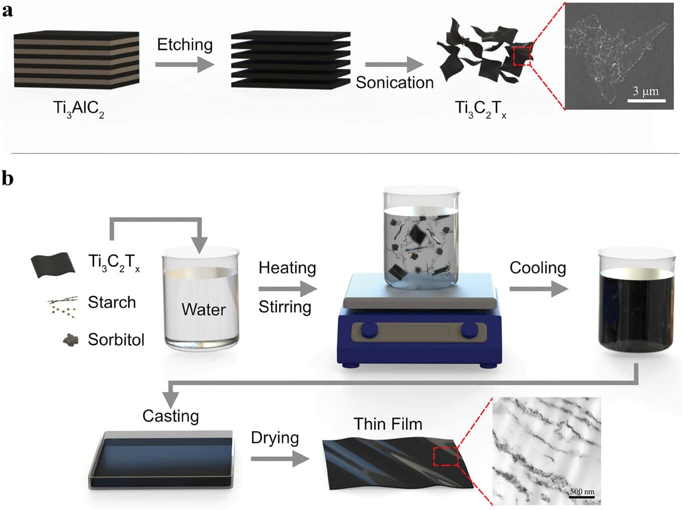

Researchers from Queen Mary University of London (UK) have developed a promising eco-friendly material. The foundation is starch, a biodegradable polysaccharide, and a film-forming agent derived from plants (corn, potatoes, and peas). Its advantages include good solubility in water and a comparatively low cost relative to other polymers (cellulose, lignin, and proteins). Moreover, starch contains hydroxyl groups, which allow for cross-linking, or the formation of intermolecular bonds, enhancing its durability.

Finally, it possesses essential properties for sustainable electronics, such as renewability, biodegradability in soil and water, lightweight, ease of manufacturing flexible films and gels, and biocompatibility, making it suitable for biological and medical applications. It is no coincidence that starch is widely used in both food and non-food industries as a raw material for fermentation, a component in adhesives and binders for paper, in chemical production, and in the textile sector.

As a conductive filler for the nanocomposite, materials scientists utilized a conductive composition of maxen—a titanium carbide (a layered two-dimensional material based on carbides or nitrides of transition metals). This was evenly distributed within the starch matrix and demonstrated outstanding compatibility, forming hydrogen bonds. By varying the concentrations of maxen, the researchers adjusted the strength, electrical conductivity, and gauge factor, or the sensor's sensitivity measure.

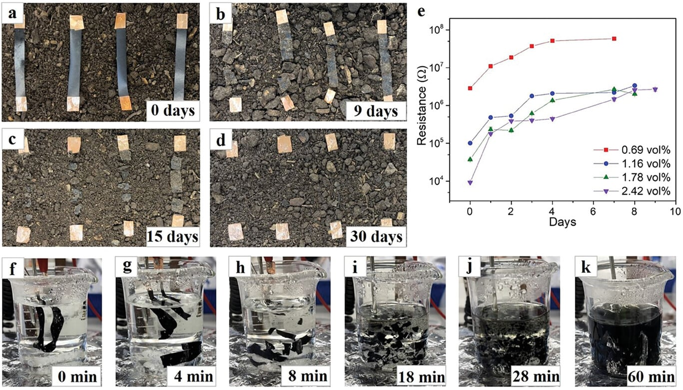

As a result, the material exhibited powerful electromechanical properties and stable electrical characteristics, enabling its use as a reliable and versatile component in electronic devices and beyond. The film can be adapted for human motion sensors and for creating electronic smart coatings.

Unlike petroleum-based analogs, the starch-based composite decomposes in soil within a month, making it environmentally friendly. The researchers presented their findings in the journal Advanced Functional Materials.